Digital Twin Warehouse: Revolutionize Your Supply Chain

YQN Operation Team | 2024.12.25 | info@yqn.com

The concept of digital twin warehouse technology is gaining attention in the evolving world of logistics and supply chain management. Digital twin solutions are transforming warehouse operations and reshaping the logistics landscape as organisations strive to improve logistics efficiency, accuracy and real-time monitoring.

What is a Digital Twin Warehouse?

A digital twin warehouse is a virtual replica of a physical warehouse. This digital model is created using data from sensors, IoT devices and real-time monitoring systems to reflect the state of the physical warehouse in a digital format. The digital twin warehouse mirrors the layout, inventory, equipment and operational processes of a real warehouse, enabling managers to simulate and optimise workflows without compromising on actual operations.

Simply put, a digital twin is like a ‘real-time’ 3D model of the warehouse, providing a real-time view of inventory, personnel movement, equipment status, tracking and managing warehouse operations from a virtual space, and providing insights that can improve decision-making and overall efficiency.

Key Benefits of the Digital Twin Warehouse

1. Real-time visibility

With a constant stream of data from IoT sensors and devices, warehouse managers can monitor equipment status, inventory levels, and even employee performance. This visibility allows potential problems to be identified and resolved in advance.

2. Predictive Maintenance

Managers can use data from the digital twin model to predict when equipment needs to be maintained or replaced. This reduces unplanned downtime, optimises asset utilisation and ultimately reduces maintenance costs.

3. Optimise warehouse layout and operations

Warehouse employees are able to visualise the entire layout in virtual space, including stock locations, workstations and equipment. By running simulations and testing different scenarios, managers can adjust layouts, workflows and inventory storage methods to optimise warehouse operations. This optimisation leads to better space utilisation and faster picking and packing.

4. Improved decision-making and strategic planning

With a digital twin warehouse, managers can simulate different scenarios, such as seasonal demand fluctuations, unexpected disruptions in the supply chain, and more. Through these simulations, it is possible to prepare for various situations in advance.

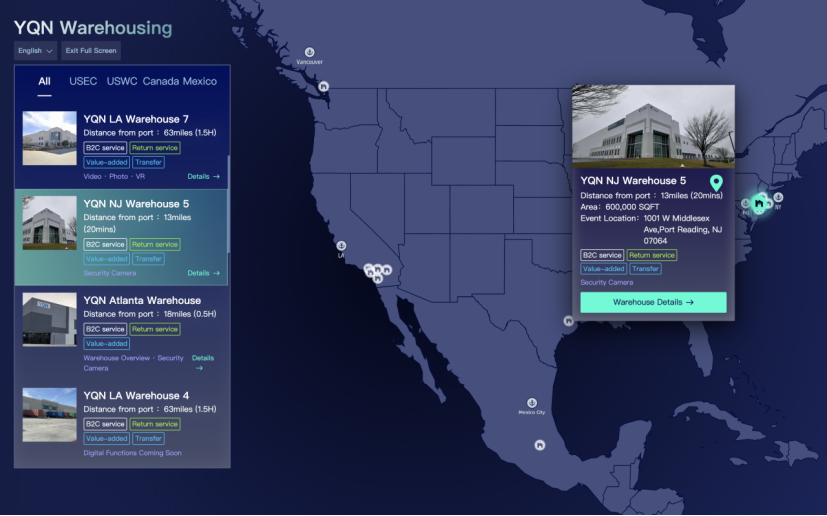

YQN’s Digital Twin Warehouse

Relying on the self-developed intelligent management system, the overseas warehouses of Lucknow are efficiently connected to online and offline channels, and accurately control the efficiency of cargo flow in the warehouses, and the intelligent system is applied to Lucknow's overseas warehouses with a total of 2,000,000+ ft. in the U.S. East, the U.S. West, the U.S. Southeast, Canada and other regions.

As the first service platform in the industry that opens up the visual real-time management of overseas warehouses to its customers, YQN has built an integrated intelligent management mode of ‘people, goods and warehouses’ , which realises the data from warehouse managers, operating forklifts to the flow of goods and significantly improves the safety and reliability of remote management.

Through the exclusive account, customers can ‘visually’ grasp the real-time information such as the location of goods on the shelves, the quantity of inventory, the situation of shipment, the path of shipment, etc., so as to make the management of inventory more transparent, and to give remote management a higher sense of ‘security’.

Not only limited to the warehouse management, shipping to the place also opened up the whole process of information nodes before entering the warehouse and after leaving the warehouse, to achieve a more efficient flow of goods. For example, it obtains the bill of lading number of the customer's container in advance, accurately understands the arrival time of the goods, and arranges for unloading of the goods at the port in advance. This connection of the whole process information makes the flow of goods in different links smoother and the service more flexible.

Of course, if you want to know more about shipping to overseas warehouses, please contact info@yqn.com.

The Future of Digital Twin Warehouse Technology

As digital twin technology continues to evolve, so does its application in the warehouse and logistics sector. The integration of Artificial Intelligence (AI), Machine Learning (ML) and automation will enhance the capabilities of digital twin warehouses. AI-driven systems can predict demand fluctuations, optimise supply chains and even automate certain warehouse operations, making this technology even more powerful.

Additionally, as 5G connectivity becomes more prevalent, the ability to collect and process data in real time will be enhanced, making digital twin warehouses more responsive and efficient. The combination of digital twins with other industrial technologies such as robotics, self-driving cars, and blockchain will pave the way for the fully automated, data-driven warehouses of the future.

Conclusion

Digital twin warehouse technology allows businesses to optimise operations, reduce costs and improve overall operational efficiency by providing real-time visibility, increased efficiency and data-driven decision-making. As technology advances, the digital twin warehouse will become an essential tool for organisations to remain competitive in the fast-paced world of supply chain management.

Today, digital twin warehouse technology can improve business competitiveness, streamline warehouse operations, increase customer satisfaction and prepare for future challenges in logistics.If you want to get more information about shipping to where overseas warehouse, please feel free to contact info@yqn.com.