Hundreds of Containers of Goods

Have Been Relocated to the YQN US Warehouse

Recently, a Chinese consumer electronics brand completed a months-long relocation project in the US. The relocation volume exceeds hundreds of containers, which were moved from three other warehouses to YQN US warehouse #3.

The customer's goal of relocation was clear. It was to choose a reliable long-term warehouse partnership and improve the supply chain collaboration.

This Chinese brand has been expanding overseas for many years, with products exported to multiple countries including Europe, North America, Southeast Asia, and Latin America. The exported products cover medium and large-sized electronic consumer goods and the brand has gained popularity worldwide, however, new challenges have emerged, such as how to upgrade and manage the supply chain system across different regions and sales channels?

This large-scale relocation is one of the important measures taken by the customer to upgrade their management. Considering domestic and international business collaboration, real-time warehouse management, and rapid development of the customer business, YQN US warehouse provided a satisfactory and reliable solution.

Pain Point 1: Difficulty in Domestic and Overseas Collaboration

The customer's global expansion develops rapidly, with over 10 manufacturing factories in China and more than 40 destination ports for transportation worldwide. So how to ensure effective collaboration across the entire supply chain is crucial.

Overseas warehouse operations involve inventory management and product distribution, which are critical parts of the entire supply chain. However, the customer's original overseas warehouse was operated by local teams, who communicated with the Chinese management team only by emails and phone calls. The Chinese management team was unable to have real-time knowledge of the details, from the storage and shipment of goods to the allocation of inventory.

Solution: Digitization + Localization

Real-time Collaboration between YQN China and YQN US Team

YQN has 24 subsidiaries worldwide, covering North America, Southeast Asia, and Latin America. Through a digital business system, the Chinese team and overseas teams can collaborate efficiently online. The domestic Chinese team communicates the customer's needs and the local overseas team responds and executes. Customers do not need to communicate with overseas teams across time zones, thus improving communication and collaboration efficiency between domestic and international teams.

During this relocation, the Chinese team took only one week to complete the overall planning, and the YQN US team quickly arranged the relocation. Dozens of trucks delivered goods to the warehouse every day, and then the US team carefully arranged the placement in the shortest time, ensuring that the customer's daily sales and the movement of goods were operated normally. The relocation project won great acclaim from the customer.

Once the goods enter the overseas warehouse, the YQN digital system allows for real-time monitoring of inventory changes and the quantity of inbound and outbound shipments on different channels. This eliminates the need for manual communication and improves management efficiency.

Pain Point 2: Difficulty in Online and Offline Channels Coordination

Expanding into overseas markets requires a multi-channel approach. In the past two years, the customer has continuously expanded their presence on both online e-commerce platforms and offline traditional supermarkets and large stores. With the increase in channels, the management of the supply chain system across multiple channels needed to be upgraded accordingly.

Currently, traditional overseas warehouse management generally faces several problems. They lack a complete digital system and cannot be seamlessly connected with various channels, especially offline traditional retail channels. Inbound and outbound shipments on different channels can only be manually counted, and the stocking requirements of different channels require manual communication, statistics, and advance planning. Once the market experiences rapid changes, it is difficult to obtain information in a timely manner and respond accordingly. Especially during the peak sales season, it is easy to miss opportunities due to uneven stocking.

Solution: One-click Connection for All Channels

YQN digital management system can comprehensively connect different online and offline channels, including mainstream e-commerce platforms such as Amazon, Wayfair, eBay, The Home Depot, Walmart, and Bestbuy, as well as supermarkets and large stores. The system is connected to over 80% of the middle and large-sized sales markets in the United States. Through the digital system, real-time shipping information from different channels can be obtained, helping customers adjust and arrange stocking and replenishment in a timely manner, and coordinating with rapid market changes.

At the same time, YQN digital management system has integrated with last-mile express delivery service providers such as FedEx and UPS. It intelligently recommends the most optimal last-mile delivery combination based on the customer's market distribution to effectively control overall costs and improve efficiency.

Currently, YQN has launched customized inventory report services, allowing customers to optimize warehouse stocking management based on comprehensive data analysis. It can even be used to derive production-side planning, which could form a flexible supply chain system.

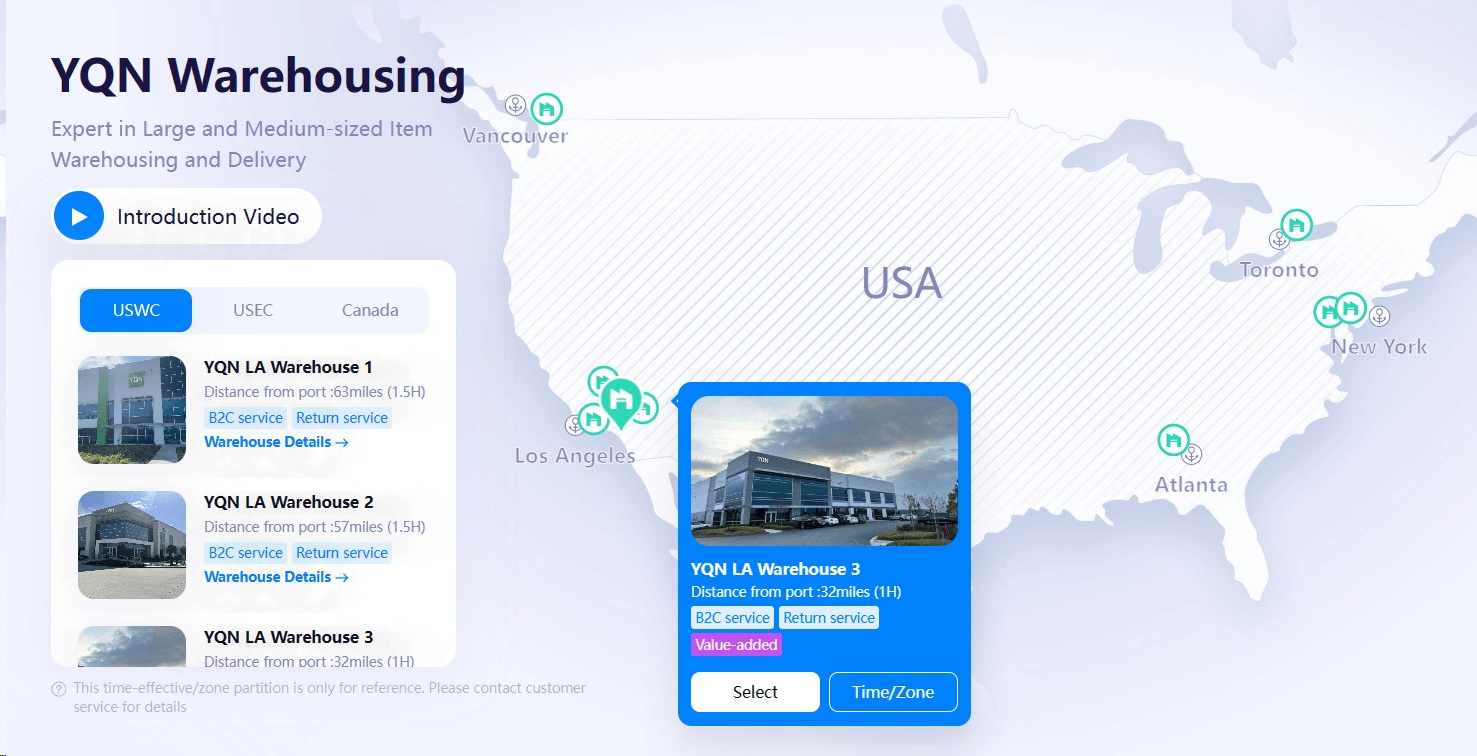

Photos of the YQN US Warehouse

YQN: Professional Supply Chain Services Upgrading

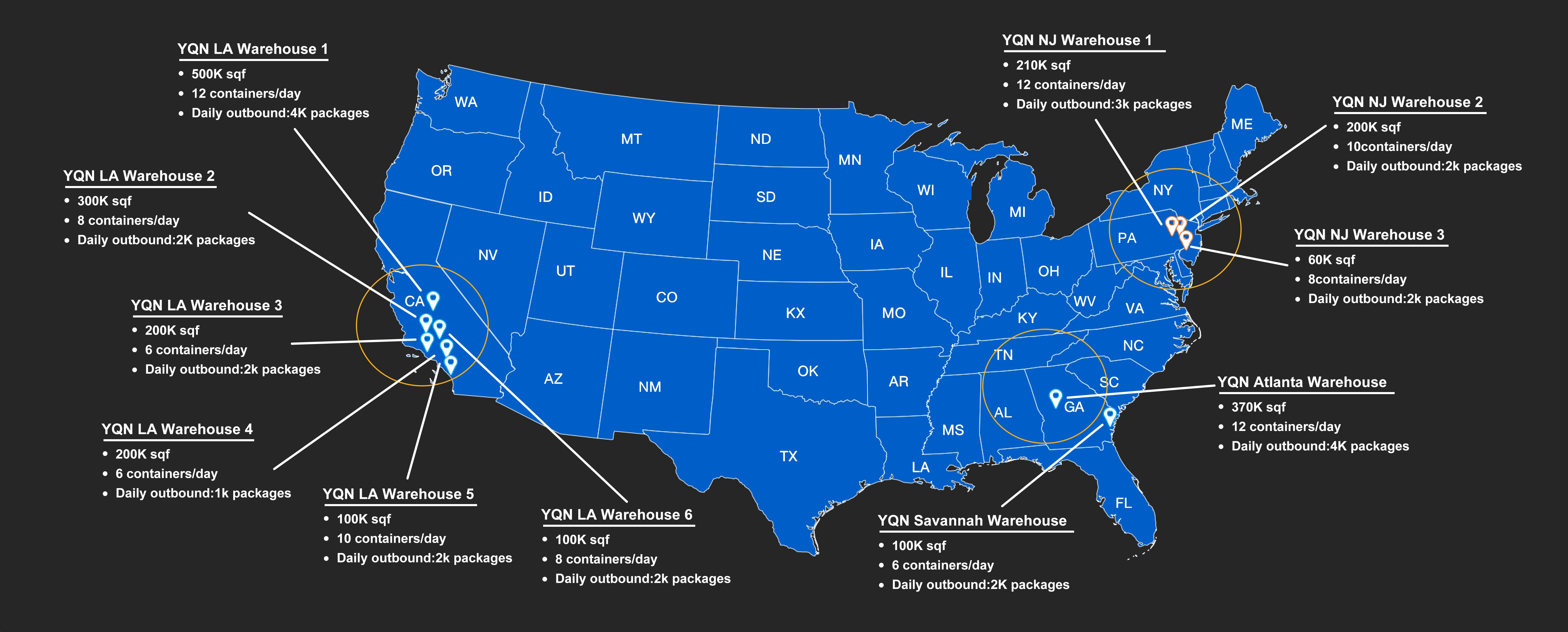

YQN overseas warehouse business, officially launched in early 2023, currently focuses on the North American market, covering Los Angeles, New Jersey, Savannah, Atlanta, Toronto, and Vancouver. The YQN US warehouse, over 2 million square feet of storage space, is managed with precision by the YQN Chinese team with over 20 years of the industry. They specialize in providing professional services to industries such as smart mobility, sports machinery, automotive parts, furniture, home furnishing, outdoor gardening, and service robots. On average, they could handle over 30,000 orders daily.

It is worth mentioning that YQN overseas warehouse business is an extension of our core logistics services such as sea freight, air freight, and rail freight. We have developed a full-chain digital solution, connecting first-mile sea freight, overseas warehouses, and last-mile delivery. This further enriches YQN’s global end-to-end international logistics solutions.

---

YQN Operation Team

info@yqn.com